Appendages design

Much of the noise experienced on board is actually caused by the water flow around the hull and appendages.

To be able to reach below 65 dB it is critical to not only focus on engine and ventilation induced noise but also eliminate flow induced noise sources. It is therefore essential to pay attentions to all appendage and recesses to the hull as spray rails, sea water inlets and outlets, keels, bow thruster tunnels, etc could cause excessive noise.

By relatively small adjustment and correct fairing the noise could be significantly reduced. Also the air flow over superstructure could cause excessive flow noise. Flow offers design review and recommendations or new design of appendages that eliminates turbulent flow or cavitation induced noise.

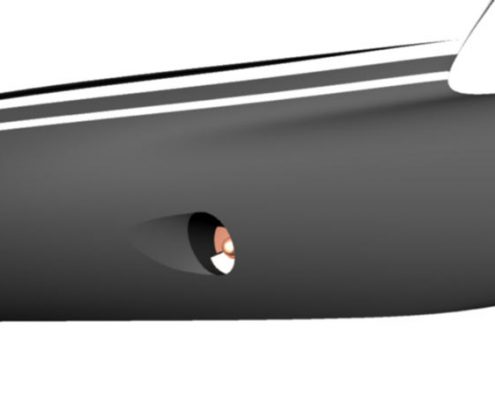

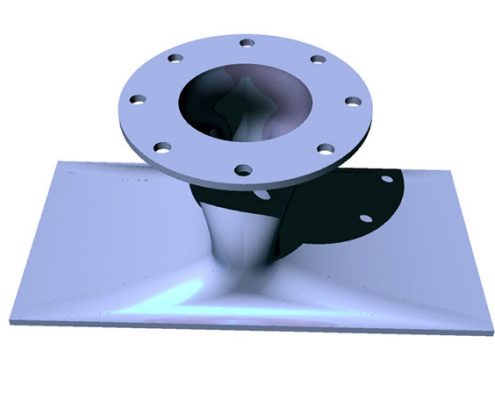

Cavitation free sea water inlets

For speeds about 30 knots and above the water could very well start cavitate around obstacles or recesses with too sharp curvature. Such cavitation could very well block the inflow through a sea water inlet or cause erosion damages to hull or appendages.

The traditional interceptor or wedge behind the an inlet could be very efficient to increase the inflow pressure, but it is a noisy solution that will cavitate at higher speed. Flow offers to design cavitation free inlets that have proven to be efficient and caviation free for speeds up to 70 knots. Such inlets could and have been designed for GRP, CRP or aluminium constructions.

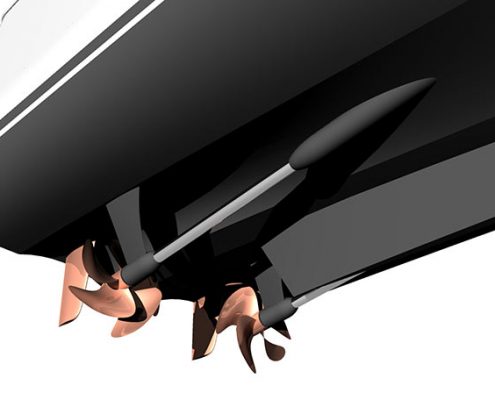

Rudder design and propulsion arrangements

Flow offers hydrodynamic design of rudder and propulsion arrangements including general dimensioning of propellers based on hull design, speed profile and installed power. This could include propeller tunnel design for already existing hulls.